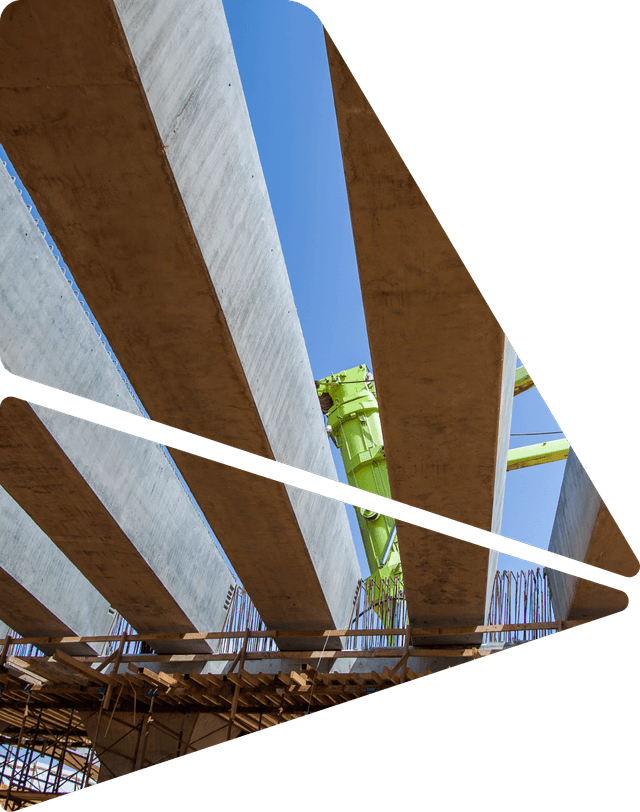

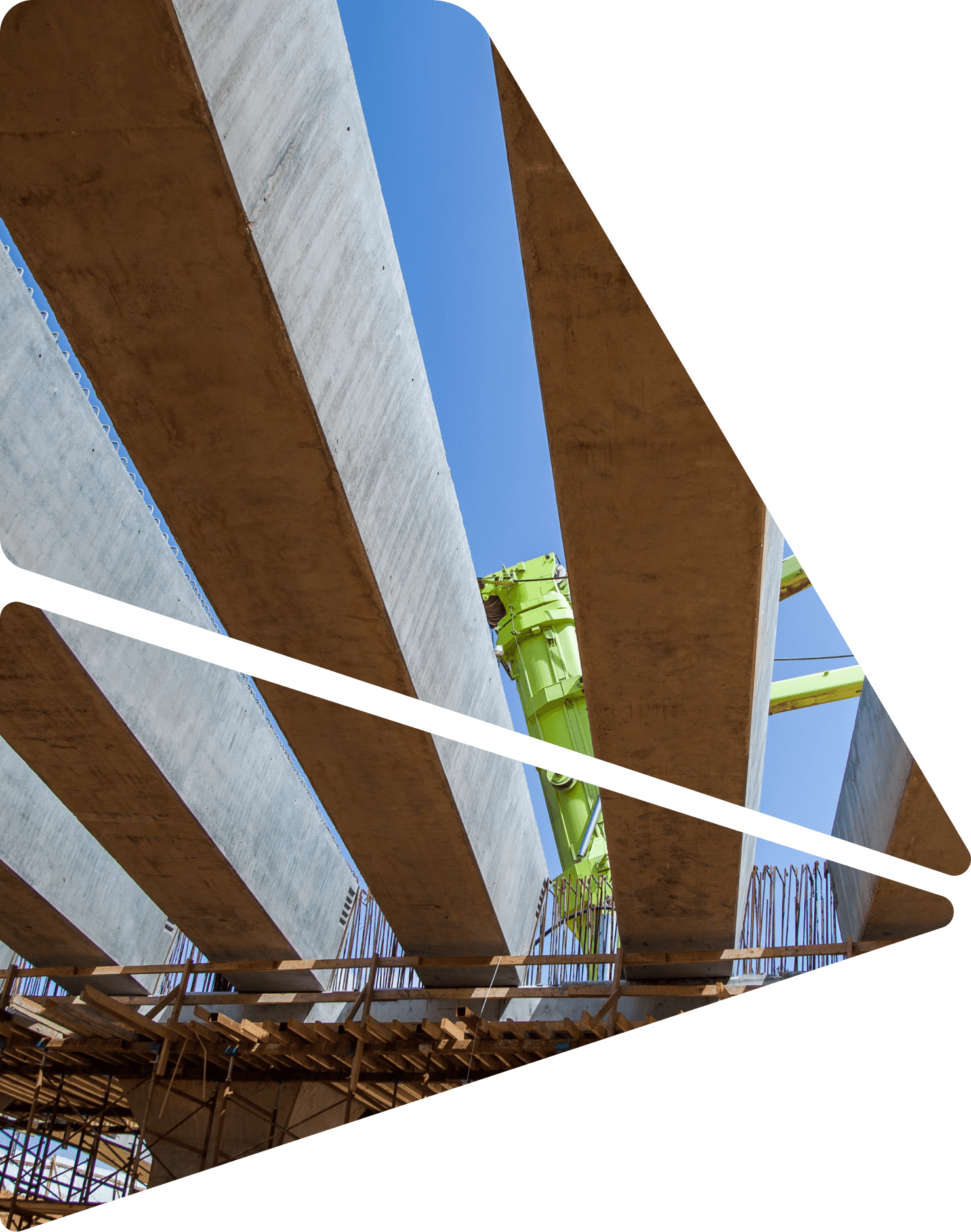

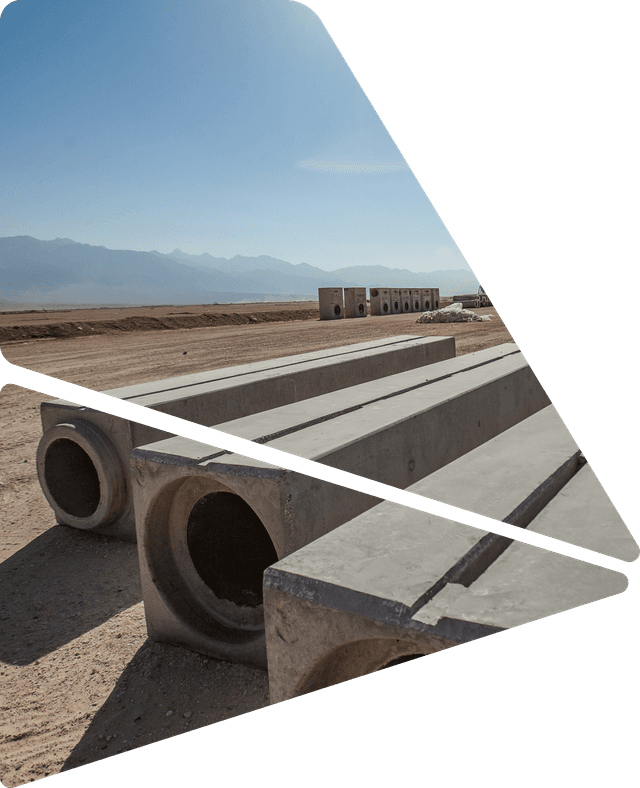

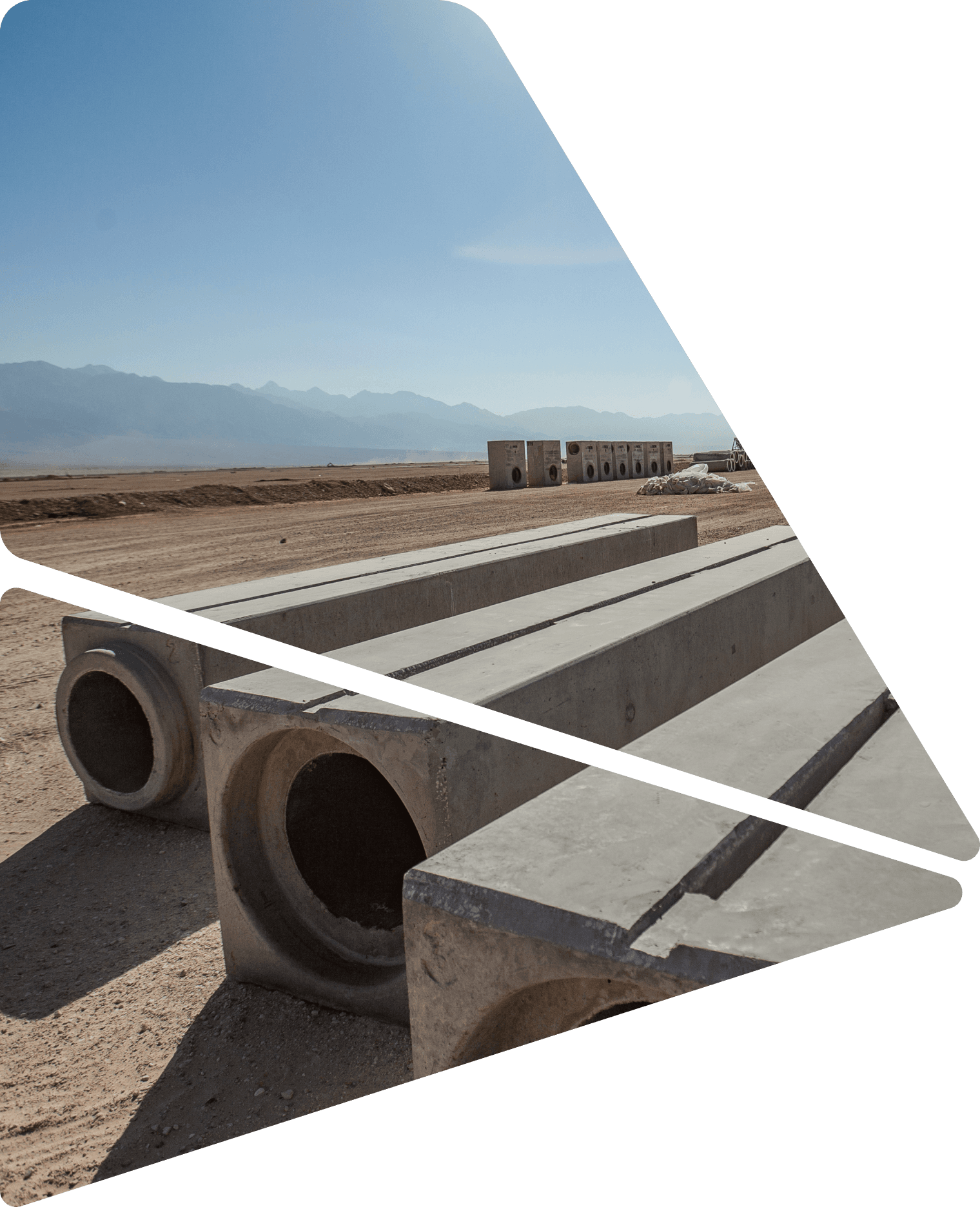

Prefabricated Solutions for Efficient Construction

Ashcrete is a leader in the design, production, haulage, and assembly of prefabricated construction elements, including hollow core slabs, prestressed concrete beams, facades, precast concrete columns, and safe room structures. Produced in Ashcrete’s factory, these elements streamline construction processes and ensure high efficiency.

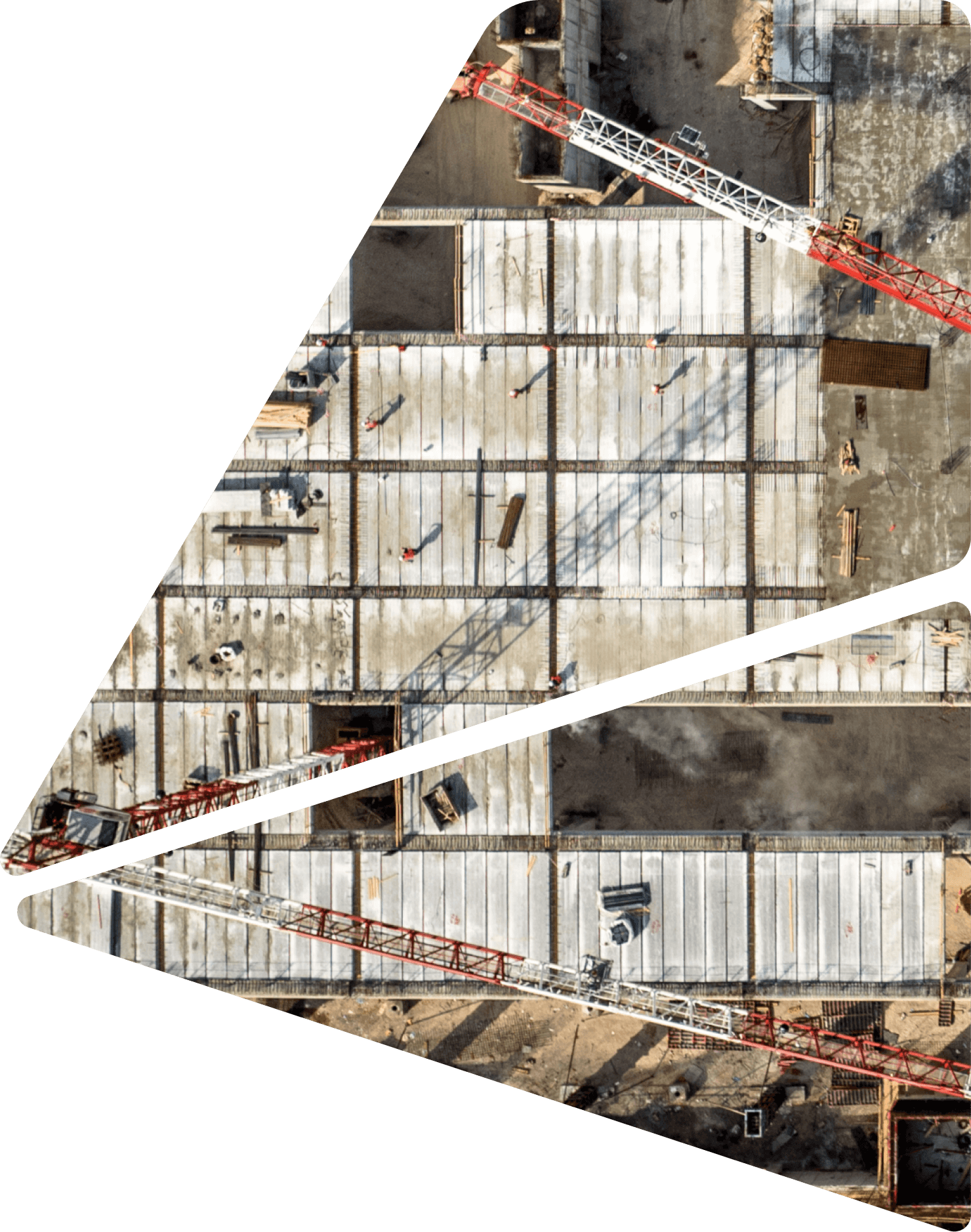

Advanced Manufacturing and Haulage Processes

Ashcrete uses advanced production technologies, backed by a cutting-edge planning department and concrete laboratory, to develop innovative solutions for large-scale projects. Its sophisticated logistics system ensures efficient haulage, flexible storage, and expert on-site assembly. The company adheres to strict production, quality, and safety standards.

Prefabricated Elements for Construction

Ashcrete produces a wide range of building elements, including 500 thousand sq.m. of hollow core slabs annually, prestressed concrete beams, large precast columns, tunneling and bridge segments, and prefabricated room structures. These elements enable fast, efficient construction of infrastructures, residential buildings, office towers, commercial complexes, and security-related facilities.

An Advanced Planning Department

Unlike most industrial plants in Israel, where design processes are typically outsourced, all elements produced at the Ashcrete plant are designed in-house by an experienced team. This in-house design team offers innovative solutions to evolving challenges, using specialized software for efficient and accurate planning. This approach minimizes errors, shortens timelines, and conserves resources.

Our Concrete Lab

Ashcrete contributes to large-scale engineering projects that demand precise, efficient control. Our concrete lab, equipped with advanced testing technologies, ensures material quality, durability, and compliance with rigorous standards. Tests cover raw materials like cement, sand, gravel, and water, as well as fresh and hardened concrete. Approved by the Israeli Standards Institute, the lab conducts tests on fresh concrete properties, compressive strength, concrete composition, and environmental resistance.

The Advantages of Prefabricated Construction

Industrialised construction provides a speedy and efficient alternative to the conventional building method. The use of industrialised elements makes construction faster, enabling progress with different stages of the building operation concurrently, with meticulous quality control at the production lines.